Insights and News

Duplex steel

Austenitic-ferritic steels, also called duplex, have a mixed structure of austenite and ferrite. It is a hybrid chromium steel: the chromium content ranges from 18 to 26% and that of nickel from 4.5 to 6.5%, insufficient quantities to determine a totally austenitic microcrystalline structure (which therefore remains partly ferritic) . Almost all of its variants contain between 2.5 and 3% molybdenum. There are also forms of Duplex, called “poor”, which do not contain molybdenum and have nickel contents lower than 4.5%.

The basic properties are:

- peculiar microcrystalline structure known as duplex, austenitic and ferritic, which gives more resistance to stress corrosion cracking;

- greater degree of passivation due to the higher chromium content (and the presence of molybdenum) and therefore better resistance to pitting corrosion than 18-8 steels;

- good weldability and moldability;

- high tensile strength and yield strength.

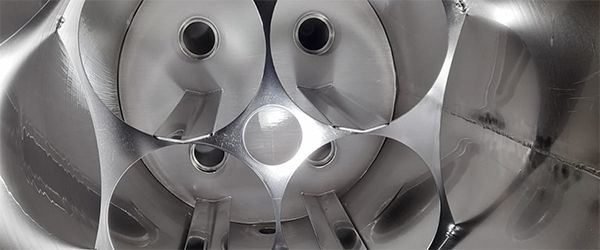

The most common uses are: heat exchangers, material handling machines, tanks and vats for liquids with a high concentration of chlorine, sea water chillers, desalinators, plants for food brine and groundwater and rich in aggressive substances.