Insights and News

Electropolishing of stainless steel

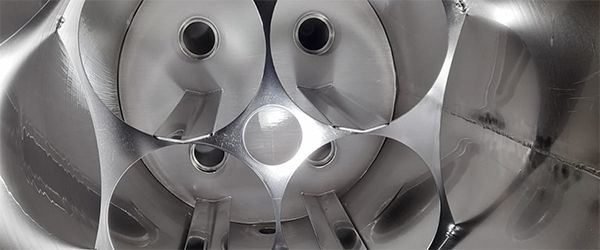

Electropolishing is a process / treatment of the family of galvanic processes which, however, acts by removing material, which therefore works exactly in the opposite way to the addition of material such as nickel plating, chrome plating, etc.

If we looked at a small piece of stainless steel under the microscope we would notice that this is formed by small ridges on the surface, even if not visible to the naked eye, these small ridges with the help of electropolishing, are eliminated, or at least made milder.

Therefore, by eliminating or at least attenuating these small ridges, the stainless steel is made as smooth as possible, giving it that glossy finish, typical of electrochemical polishing, and points for possible grip and triggering for future oxidation problems are eliminated.

Furthermore, with the removal, the carbon particles that may already be present in the metal, due to mechanical processing, are also eliminated. So with electropolishing we get the following advantages:

- reduction of the roughness profile (we can decide the degree of roughness)

- elimination or attenuation of microbave

- increased resistance to corrosion (this does not exclude passivation)

- removal of contaminants

- glossy surfaces, with a good aesthetic-decorative aspect

The fields for APPLYING ELECTROPOLISHING ARE MANY:

- PHARMACEUTICAL

- FURNITURE

- AEROSPACE

- AUTOMOTIVE

- OIL & GAS

- VARIOUS PLANTS